Hunter OEM Parts

General Marine Parts

refurbishing aluminum water tanks

posted 09-11-2016 by eianm

Refurbishing a worn aluminium tank

As was very common from the 1950’s through until probably well into the 1990’s, my 25 year old Hunter 42 has aluminium tanks. The fuel tank is in great condition, confirmed after recently adding 2 x inspection ports and cleaning that tank for the first time in 25 years, but that’s a separate story!

I have 2 x aluminium water tanks- one amidships and one forward. Both, as one should expect, had some corrosion. My forward tank had been leaking very slightly, so I knew that needed replacement. However, to replace that tank is a HUGE undertaking, requiring the removal (read major deconstruction) of the entire guest bed and drawers, plus removal of the door and frame into the forward cabin. And then, after all that, the aluminium tank must be cut into two pieces in order to be able to remove it from the boat. Obviously this also means that the replacement plastic tank needs to be a little smaller capacity in order to be able to get it into the boat (but you only lose about 40 litres out of 260L I know very well from the sailboat owners forum that this is a VERY common conundrum for many boat owners, so I set out to research and see if a refurb. was both possible and practical. The main problem I had was to find a coating or sealant that was certified food safe, or suitable for potable water. I finally came across the Norwegian firm Jotun. Initially my internet search had found “Jotun tank guard” but unfortunately, this was not certified for use on aluminium! This is where the technical guys at Jotun were very helpful, they researched their archives and found that another product- JOTACOAT, was indeed suitable for application onto aluminium and had been NATA (Australian government certified) laboratory tested and certified as food safe , therefore, perfect for my water tank!

The job

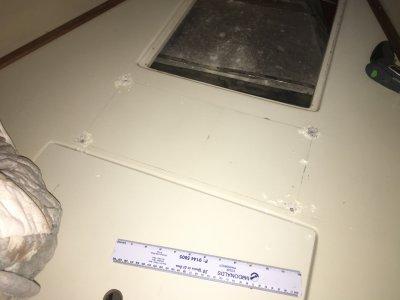

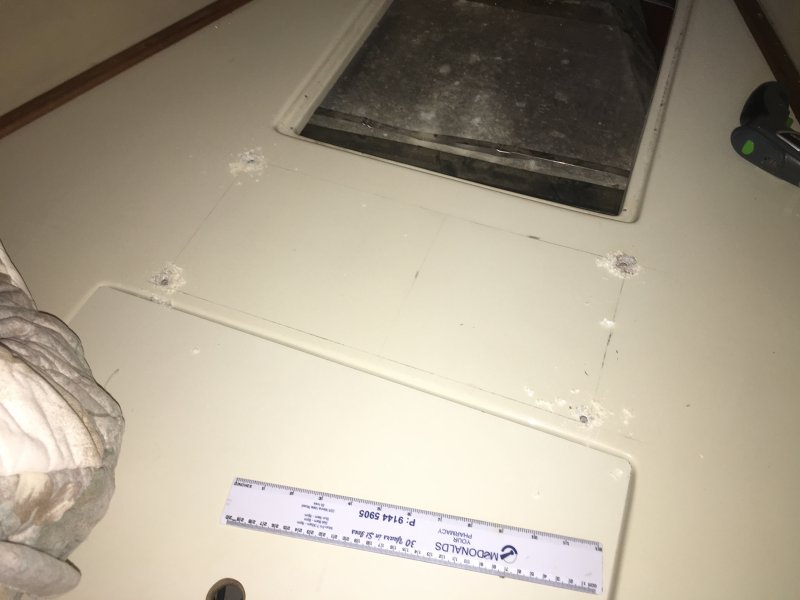

Step 1-First I had to cut a new access hole in order to access the forward section of the tank and then 2 large inspection ports into the tank, as I have two full width baffles in the tank- so, large enough to allow good access to the entire tank. See pics 0 and 1

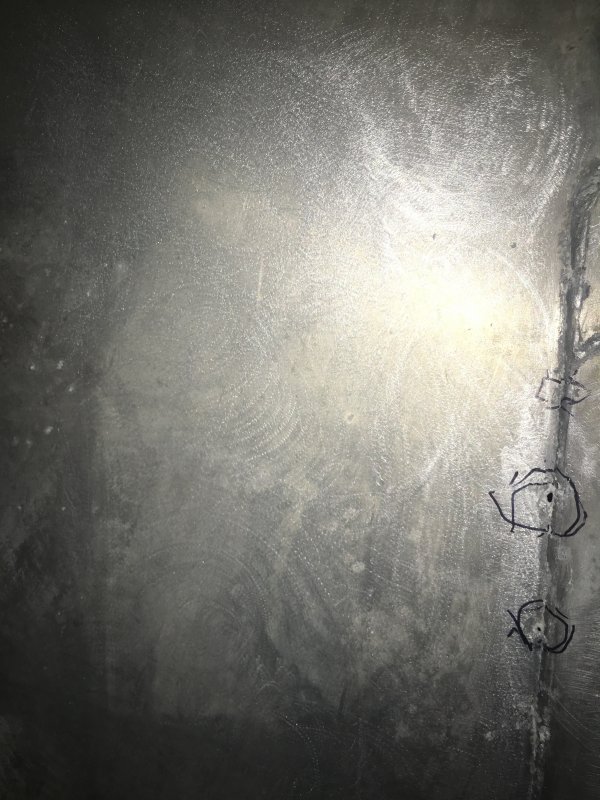

Step 2- inspect the tank- luckily the tank was in reasonable overall condition see pics 2 and 3.

Step 3- thoroughly clean all corrosion from all tanks surfaces in order to access real condition-see Pics 4 > 9.

Step 4- after having decided this was well worth a shot at refurbishing, I set to preparing the tank. Jotun advises that all surfaces must be rubbed back with coarse grit paper to provide a good “keyed” surface for the Jotacoat to adhere too. see pics 10 and 11

Step 5- I ended up with 7 holes in my tank ranging from pin holes to about 3>4mm dia. These I filled using JB water weld. In Googling, this seems to work very well in a situation like this. I pushed the water weld well into each hole and then smoothed the top side. See pics 12 > 15.

Step 6- Jotacoat is a two part epoxy based surface coating, that can be mixed in various colours- I have blue , as it was available off the shelf. I initially went over all water weld patches and all welded seams throughout the tank. I let this dry and then applied a full surface coat throughout the entire tank. I left this – well ventilated for 24 hours and then went back to do coat 2. After another 24 hours and a close inspection of al internal surfaces to ensure I was getting an even coverage, I applied coat 3. By now I had a beautiful even and thick blue Jotacoat surface throughout. It really does look great- see pics 16 .

Step 7 was to make inspection plates to cover the 2 x large 140 x 330mm holes I cut into the top of the tank. I decided to use 10mm Polycarbonate clear sheet- this is virtually unbreakable , but also will allow easy future inspection by simply lifting the mattress and the inspection panels- see pic 10.- as my tank is only 3mm thick aluminium sheet, I decided to use 304 SS m6 bolts with flat washers and a rubber gasket. See pic 17

I then filled the tank and left for 36 hours to confirm no leaks. I then drained the tank to ensure that ANY residual taint from the Jotacoat was removed before re-filling tank with lovely fresh Sydney water!

I invested about 10 hours of labour into this project. The total cost of my successful refurbishment was about $200 all up, not costing in my labour, so I consider this a VERY successful project. With a custom made plastic tank costing around $1000 , this was a no-brainer- not to mention actually a whole lot faster and much easier.

As was very common from the 1950’s through until probably well into the 1990’s, my 25 year old Hunter 42 has aluminium tanks. The fuel tank is in great condition, confirmed after recently adding 2 x inspection ports and cleaning that tank for the first time in 25 years, but that’s a separate story!

I have 2 x aluminium water tanks- one amidships and one forward. Both, as one should expect, had some corrosion. My forward tank had been leaking very slightly, so I knew that needed replacement. However, to replace that tank is a HUGE undertaking, requiring the removal (read major deconstruction) of the entire guest bed and drawers, plus removal of the door and frame into the forward cabin. And then, after all that, the aluminium tank must be cut into two pieces in order to be able to remove it from the boat. Obviously this also means that the replacement plastic tank needs to be a little smaller capacity in order to be able to get it into the boat (but you only lose about 40 litres out of 260L I know very well from the sailboat owners forum that this is a VERY common conundrum for many boat owners, so I set out to research and see if a refurb. was both possible and practical. The main problem I had was to find a coating or sealant that was certified food safe, or suitable for potable water. I finally came across the Norwegian firm Jotun. Initially my internet search had found “Jotun tank guard” but unfortunately, this was not certified for use on aluminium! This is where the technical guys at Jotun were very helpful, they researched their archives and found that another product- JOTACOAT, was indeed suitable for application onto aluminium and had been NATA (Australian government certified) laboratory tested and certified as food safe , therefore, perfect for my water tank!

The job

Step 1-First I had to cut a new access hole in order to access the forward section of the tank and then 2 large inspection ports into the tank, as I have two full width baffles in the tank- so, large enough to allow good access to the entire tank. See pics 0 and 1

Step 2- inspect the tank- luckily the tank was in reasonable overall condition see pics 2 and 3.

Step 3- thoroughly clean all corrosion from all tanks surfaces in order to access real condition-see Pics 4 > 9.

Step 4- after having decided this was well worth a shot at refurbishing, I set to preparing the tank. Jotun advises that all surfaces must be rubbed back with coarse grit paper to provide a good “keyed” surface for the Jotacoat to adhere too. see pics 10 and 11

Step 5- I ended up with 7 holes in my tank ranging from pin holes to about 3>4mm dia. These I filled using JB water weld. In Googling, this seems to work very well in a situation like this. I pushed the water weld well into each hole and then smoothed the top side. See pics 12 > 15.

Step 6- Jotacoat is a two part epoxy based surface coating, that can be mixed in various colours- I have blue , as it was available off the shelf. I initially went over all water weld patches and all welded seams throughout the tank. I let this dry and then applied a full surface coat throughout the entire tank. I left this – well ventilated for 24 hours and then went back to do coat 2. After another 24 hours and a close inspection of al internal surfaces to ensure I was getting an even coverage, I applied coat 3. By now I had a beautiful even and thick blue Jotacoat surface throughout. It really does look great- see pics 16 .

Step 7 was to make inspection plates to cover the 2 x large 140 x 330mm holes I cut into the top of the tank. I decided to use 10mm Polycarbonate clear sheet- this is virtually unbreakable , but also will allow easy future inspection by simply lifting the mattress and the inspection panels- see pic 10.- as my tank is only 3mm thick aluminium sheet, I decided to use 304 SS m6 bolts with flat washers and a rubber gasket. See pic 17

I then filled the tank and left for 36 hours to confirm no leaks. I then drained the tank to ensure that ANY residual taint from the Jotacoat was removed before re-filling tank with lovely fresh Sydney water!

I invested about 10 hours of labour into this project. The total cost of my successful refurbishment was about $200 all up, not costing in my labour, so I consider this a VERY successful project. With a custom made plastic tank costing around $1000 , this was a no-brainer- not to mention actually a whole lot faster and much easier.