Hunter OEM Parts

General Marine Parts

Trailer Rebuild

posted 01-20-2017 by Doug J

This is a picture of my 1994 H26 sitting on its original and improved trailer.

Given the fact the main parts of the trailer are galvanized it was basically in good condition and worth rebuilding. The investment in new parts including tires came to around $1500. Considering the cost of a new trailer could be as much as $6000, I figure it was well worth the investment of time and money.

I also prefer the look of the old original trailer with its scalloped fenders and guide-posts. The PO did add additional support bunks under the bow as well as the side guides.

Given the fact the main parts of the trailer are galvanized it was basically in good condition and worth rebuilding. The investment in new parts including tires came to around $1500. Considering the cost of a new trailer could be as much as $6000, I figure it was well worth the investment of time and money.

I also prefer the look of the old original trailer with its scalloped fenders and guide-posts. The PO did add additional support bunks under the bow as well as the side guides.

Here is a picture just after purchasing and heading home. Hard to believe, but the trailer had the original 1994 tires on it, 21 years old!!! I was told the tires were often removed and stored inside, so that may be how they lasted so long. I felt uncomfortable about the 60 mile ride home, worried I might not make it. The drum brakes did not work either! I took it slow and made it home. Considering myself lucky to make it home, I vowed not to use it again until rebuilt.

I rebuilt the trailer with the boat sitting on it, as I did not have a slip to put the boat in and did not want to pay high daily storage and hoist fees in a boat yard.

I was able to rebuild everything with the boat on it accept for the bunks, which are okay. New carpet will be installed at a future date.

I was able to rebuild everything with the boat on it accept for the bunks, which are okay. New carpet will be installed at a future date.

The axles also had considerable rust, as they are not galvanized. I thought about buying new galvanized axles, but opted to clean them up and repaint. I did extensive grinding and wire brush work. Then used Rust-Oleum Professional Primer and Enamel applying several coats. I hope the axles last several years, though I may need to replace them someday.

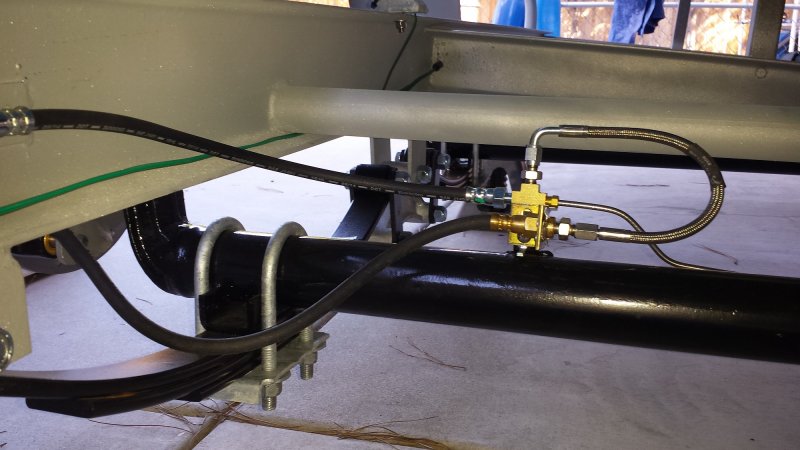

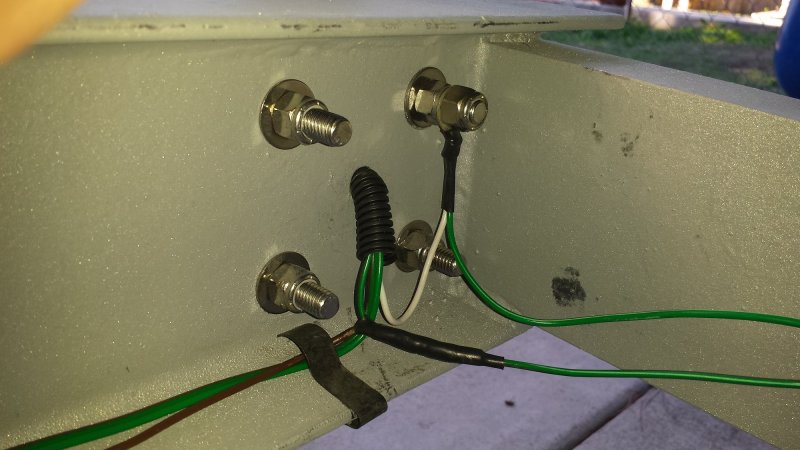

In order to keep the original tongue extension capability, the 10 ft hydraulic brake line needed to be replaced. The original was in terrible shape, dried out and cracked all over. A new replacement was not readily available, so custom braided stainless steel lines were made, which included the short piece on the brake axle.

Here you can see the additional guides installed by the PO. The side guides are made of heavy aluminum square tubing, very strong and helpful centering the boat while putting back on trailer. Also, you can see the additional bunk supports for the bow.

New bunk carpet will finish the job.

New bunk carpet will finish the job.