Hunter OEM Parts

General Marine Parts

Window Fix

posted 10-11-2017 by swidmier

I had major cracking around the window caused, again, by the trapped air that heated up. In fact, the windows practically fell out when I tugged on them because the expansion of these cracks broke the seal. Thought I would share some photos of fixing this issue. As I said in my other article, I used Plexus and Devcon plastic weld with fiberglass tape on top, I first drilled holes at the end of the cracks to keep them from spreading and used a dremel with spiral cut to open the cracks a bit.

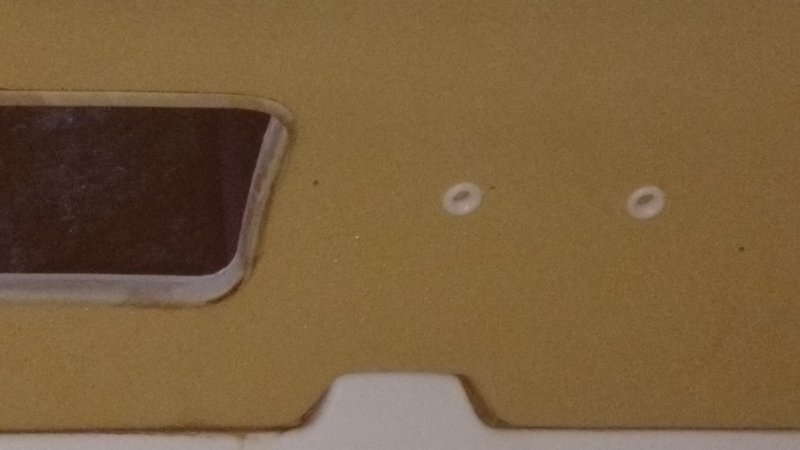

I again faired everything with bondo and sanded it smooth. Again, I would recommend thickened epoxy instead. I also drilled holes to install the two inexpensive louvered mini vents I bought on Amazon. The goal is to prevent heat buildup behind the plexiglass which causes the cracking of the plastic.

On the inside I trimmed up the holes using through-deck fairleads that can be found from a number of marine suppliers. I finished up by remounting the windows using outdoor double stick mounting tape and black caulk. The windows didnt seat perfectly flush so I ended up drilling some small holes and driving screws in at strategic points. Not perfect but also not ready to fall out and they are watertight...had a couple of hurricane remnants to test that out.