Hunter OEM Parts

General Marine Parts

Dont be afraid of cracks!

posted 10-11-2017 by swidmier

I got my Hunter 212 fairly cheap knowing I would have to do a lot of work. It is one of the early (2000) boats and there were a lot of cracks. Fortunately, the foam which gives the boat its structure was sound so the only thing I was doing was fixing the skin. I followed the instructions provided on this site.

My Hunter 212 was an early one (2000) and neglected by its previous owner so had a LOT of cracks. Fortunately, the foam core which provides the structure was completely sound so all I had to do was fill a TON of cracks. I followed the instructions provided on this website but thought I would share the pictures.

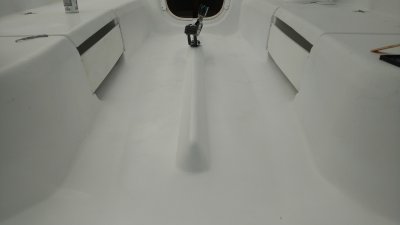

First step was to drill holes at either end of the cracks (sometimes feet apart). Then I used a dremel with a spiral cut blade to open up the cracks to allow the plastic weld to get down inside. I used both the Plexus that is recommended (big tube with mixing nozzles) and then Devcon Plastic Weld when the big tube ran out. I set fiberglass tap on top of the plastic weld before it set for extra structure. This photo shows the cracks filled with the plastic weld and fiberglass cloth tape.

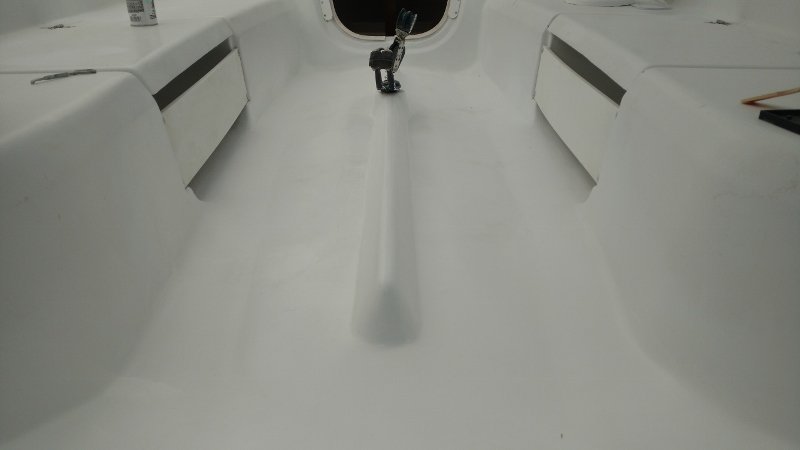

I was concerned about gaps between the plastic skin I was repairing and the foam core. These gaps would trap air that would heat up and cause the plastic to crack again. So, I drilled holes and poured in epoxy then put weights over the skin to cement it back down. Still probably have voids but I know where I can buy more Devcon plastic weld for future cracks. I painted with a good primer and then, following some great advice from this site, sprayed with Krylon Fushion gloss white which proved to be an almost perfect match. I found Krylon Fushion in stock at my local Ace Hardware.

I bought some stuff call Treadmaster on Ebay that came with adhesive already on it. I went ahead and put this on the cockpit floor to provide a non-skid surface, hide our Georgia mud, and hide my impatience with sanding. It does get a little hot in the Florida sun but a bucket of scooped water cools it right down.